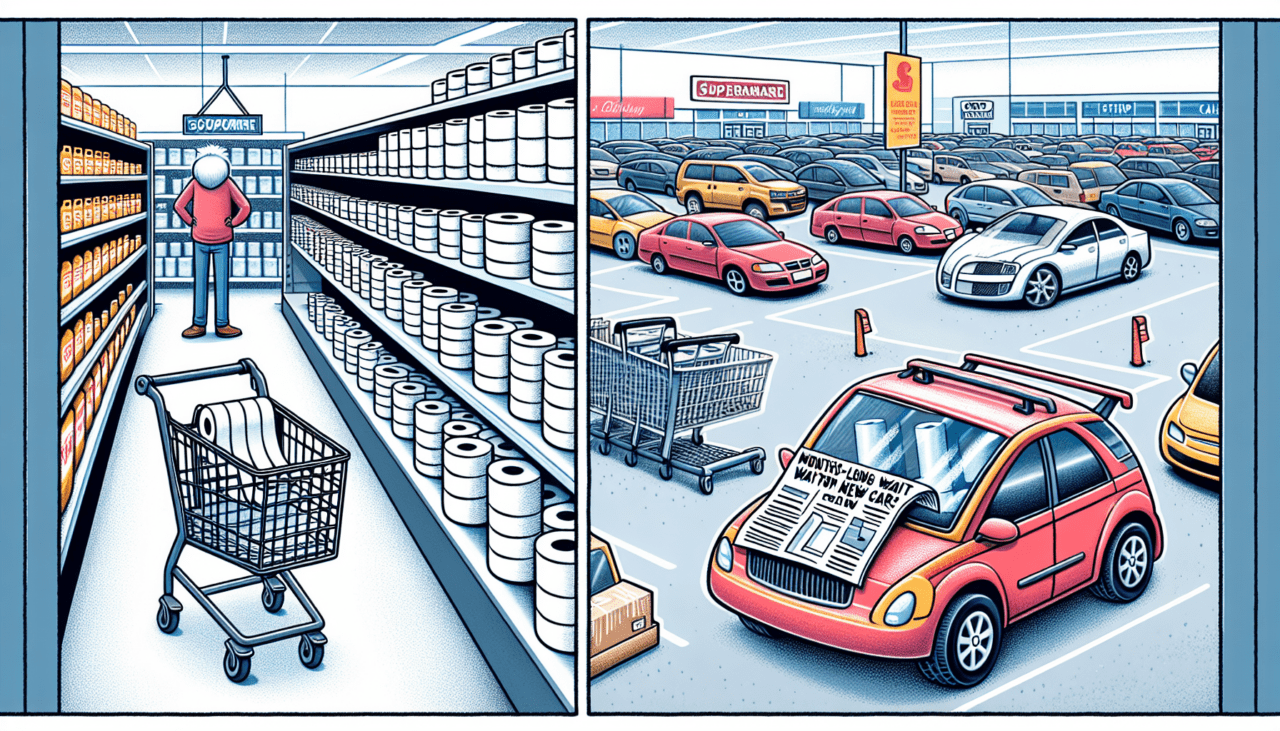

It felt like the world’s plumbing for goods just got clogged everywhere at once. For most of us, it was a bizarre inconvenience. For businesses, it was a harsh wake-up call. It showed just how interconnected, and fragile, our global systems are. Suddenly, phrases like “supply chain disruption” weren’t just business jargon; they were headlines we all understood. And it became crystal clear that simply having a supply chain isn’t enough anymore. You need one that can bend without breaking, one that can see trouble coming and reroute itself. This is where the concepts of Supply Chain Resilience & Smart Logistics really step into the spotlight. It’s about building muscles and adding intelligence to how goods move around the planet.

Why the Old Ways Just Aren’t Cutting It Anymore

For decades, the name of the game in supply chains was efficiency, often defined purely by cost. How cheap can we make it? How lean can we get our inventory? This single-minded focus worked reasonably well in stable times. But when the world throws a curveball – a pandemic, a trade war, a sudden natural disaster – those super-lean, hyper-efficient systems can buckle spectacularly. We built these incredibly long, complex chains, optimized for sunny days, and didn’t really prepare for the storm.

Vulnerability to Disruptions

Think about relying on a single supplier, maybe halfway across the world, because they offer the lowest price. When that supplier’s factory floods or their region goes into lockdown, you’re stuck. This single-sourcing strategy, while cheap on paper, creates immense risk. Add to that a lack of real-time information – not knowing exactly where your goods are at any given moment – and you’re essentially driving blind in foggy conditions. You can’t react quickly if you don’t even know there’s a problem until it hits you square in the face.

Slow Response Times

- Orders are often processed manually, leading to delays and errors.

- Communication between different partners in the chain might be siloed and inefficient.

- Changing routes or shifting inventory locations requires significant human intervention.

Building a Supply Chain That Can Weather the Storms

Okay, so the old model is shaky. How do we build something stronger, something that doesn’t crumble at the first sign of trouble? It’s not about building a wall; it’s about building a system that’s flexible, informed, and connected. It’s about moving from just-in-time (JIT) to just-in-case (JIC), but doing it smartly, without losing all the efficiency gains we’ve made over the years. This is where true supply chain resilience comes into play.

Enhancing Visibility and Data Sharing

If you can’t see it, you can’t manage it. Visibility is the absolute cornerstone of resilience. This means having real-time, end-to-end insight into your entire supply chain, from the source of raw materials all the way to the final customer delivery.

- Tracking goods in transit across multiple modes (ship, rail, truck, air).

- Monitoring supplier performance and potential risks.

- Understanding inventory levels across all locations instantly.

When you have this kind of data, you can spot potential issues much earlier, whether it’s a delay at a port or a quality problem with a supplier. This allows for proactive decision-making rather than reactive damage control.

Creating Flexibility and Redundancy

Building resilience means having options. Instead of putting all your eggs in one basket, you diversify. This could mean having multiple suppliers for critical components, located in different geographic regions. It might also involve having redundant logistics partners or alternative transportation routes mapped out in advance. While this might seem more expensive upfront, the cost of a complete shutdown due to lack of options is far, far higher. It’s about strategic investment in robustness.

How Supply Chain Resilience & Smart Logistics Work Together

Resilience is the goal – the ability to withstand and recover from shocks. Smart logistics is largely how you achieve it in today’s world. Smart logistics isn’t just about faster delivery; it’s about using technology and data to make logistics processes intelligent, predictive, and automated. It provides the tools and the brainpower that a resilient supply chain needs to function effectively in chaotic times. It’s the engine that drives the resilient system.

Leveraging Automation and AI

This is where logistics gets its “smart” label. Automation can handle repetitive tasks faster and more accurately than humans, from automated warehousing systems to drone deliveries. But the real power comes from artificial intelligence and machine learning. AI can analyze vast amounts of data to predict potential disruptions, optimize routes in real-time based on traffic or weather, and even manage inventory levels dynamically.

- AI algorithms predict demand fluctuations, reducing stockouts or excess inventory.

- Automated guided vehicles (AGVs) move goods efficiently within warehouses.

- Machine learning optimizes delivery routes considering multiple variables simultaneously.

The Role of Digitalization and Collaboration

Digitalization is the foundation. It means moving away from paper and manual processes to interconnected digital systems. This enables seamless data flow between different parties – suppliers, manufacturers, distributors, logistics providers, and customers. Platforms that allow for shared visibility and collaborative planning are crucial. This interconnectedness allows everyone in the chain to be on the same page and react together when things go wrong, fostering a more collaborative and agile ecosystem. It turns the linear chain into a connected network.

Moving forward

Building a resilient and smart supply chain isn’t optional; it’s a necessity for survival and competitive advantage. It requires investment in technology, a willingness to share data, and a shift in mindset from purely cost-focused to risk-aware and agile. Start small by focusing on gaining better visibility into one part of your operation, or pilot a smart automation tool in your warehouse. Talk to your partners about sharing data more effectively. The journey might seem daunting, but taking those first steps towards greater intelligence and flexibility will pay dividends when the next unexpected disruption inevitably arrives. It’s about being prepared, not scared.